1 inch blinds for mobile home

These are the cheapest blinds you can buy from Wal*mart.

And this is the cheapest USB power supply brick with adequate current found in the checkout isle of Wal*mart.

What are you making the post for? 1 inch “mini blinds” don’t have enough room inside the housing to install any type of electronics if thats what you are getting at.

Living in a mobile home, I’m finding all the doors and windows are not the same as normal housing. My windows are flush mounted and have no sill. Although, there is about a one inch space between the inner(storm) window and the outer window, allowing enough space to fit 1 inch blinds. I have 8 aluminum vertical sliding windows and 2 aluminum horizontal sliding windows.

As you can see in the pictures, the tilt rod is on the side of the non sliding/opening side. So, I can only reach in and turn the rods when the windows are open and the blinds up. It’s a real pain in the ass! Here are pics of a finished vertical sliding window…

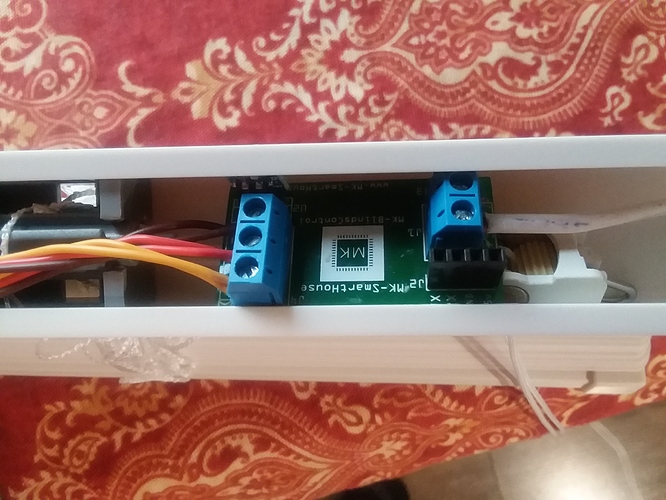

Yes, these are 1 inch blinds fitted with Matt’s / mattkaczynski blinds controller kit installed. Next I will show how it was done.

This is how the servo fits. It sticks out a bit, but, i can cover it up with a valence or other means.

I took the controller board out of the case and just placed it in the blinds like such.

I had a similar situation since 1-inch blinds are pretty standard around this part of the country. I put the pieces in the same way you did, except I used electrical tape to insulate the circuit board because the upper parts of my blinds are metal and a wire tie to hold the bunched up servo cable. I then lowered the blinds mounting brackets by 3/4 of an inch and it worked great.

One other thing related to using 1-inch blinds, it uses a small gear that the strings that adjust the slats are attached to and requires moving more that 180 degrees due to gear ratios. For a normal rod, this isn’t an issue because you keep turning. However, it makes a difference with a servo. I ordered a 270 degree servo and will modify the firmware to work with that. It would be nice if there was an option in the V2 firmware to allow 270 degree servos (probably boolean) for those who want to build this themselves and use a 270 degree servo.

I put the 270 degree servo (which doesn’t actually have a full 270 degree range) in and now the blinds have the full range. No code modifications necessary.

Nice! I have read it is very easy to just open the servo and take out the pin in the gear cluster for a full 360+. What about using a second servo for the pull strings? How would you go about engineering that?

It would need a way to detect when the blind was at the top or bottom (like end-stops) so it would stop spinning. Maybe that or something to monitor if the shaft of the motor is continuing to move and if it’s not, send a 1500us PWM signal to get the servo to stop. That would also work well if the blinds got caught on something so it didn’t ruin something. It would also need to spool the strings onto the servo and something could be 3D printed for that. Definitely more complicated than a slat angle adjustment.

What about just timing it? and another controller board I spose. Unless we can modify the board in such a way to split the signals…

Sure, the ESP8266 has like 10 usable GPIOs with PWM, so it could be used, however the board would need to be either redesigned or modified (i.e. wires soldered directly to the pins of the ESP8266) to make use of that. I suppose you could time it, but there’s always unexpected things that happen which alter the actual speed, so it may not be consistent and it would be a bunch of trial and error to find the closest timing.

Cool Beans! A guide hook and a small spool about the same size as the coupler would fit on the opposite side of the tilt servo. You could even take out the stop barrel and use the two string guides in place. Possibly turn them upside down? You can make easy string guides out of paper clips.

You could always mount end stops at the top and bottom positions of the window and when the weighted bar hits them then it would stop turning.